BONUS RETURN carried out both practical and theoretical work to support circular innovations in the Baltic Sea Region, in the form of pre-commercial support to three promising ecotechnologies as well as the production of a generic decision support toolbox for decision-makers interested in pushing and pulling the sector into a more circular economy.

An innovation competition was launched intended to attract emerging ecotechnologies with a potential to recycle nutrients and carbon from agricultural and wastewater by-products. The winners of the innovation challenge received support in their pre-commercialisation efforts directed towards improving their Readiness Level (RL) including adapting their innovation to local market needs.

The innovation competition award also functioned as a platform for meeting potential investors and clients. Out of approximately 15 applicants, four finalists that emerged from a jury panel evaluation were invited to present their innovations at the Baltic Sea Future Conference in Stockholm, in March 2018. In addition to the conference presentations, the candidates presented their innovations in an interview with the jury.

Three technologies were selected as winners of the innovation competition: RAVITA, developed by Helsinki Region Environmental Services Authority (HSY), TerraNova® Ultra, developed by TerraNova Energy and BiOPhree®, developed by Aquacare.

Aquacare, Netherlands

Aquacare received support through testbed trials in a relevant operational environment, a prerequisite to reach TRL 7. BiOPhree® is an ecotechnology for phosphorus removal and recovery from liquid streams that is built around phosphorus adsorption onto a proprietary adsorbent material. The process can be used to reach less than 10 µg TP/l in the treated stream. The technology can be applied to remove and recover phosphorus directly at a wastewater treatment plant or it can be set up remotely to remediate phosphorus overloaded streams and lakes, thus offering the possibility of both closing the loop on phosphorus and restoring eutrophic water bodies.

The BiOPhree® technology testbed trials resulted in the collection of operational data and information that will enable Aquacare to further develop and optimize their process. Tangible results included that the process could achieve the stated effluent quality under many but not all operating conditions, and that the need for routine maintenance, at least under the testbed conditions, was significantly higher than originally stated by Aquacare in the supplied technical documentation.

Aquacare’s Prashanth Kumar at the test site in Knivsta, Sweden. Images: SEI.

HSY’s Ravita, Finland

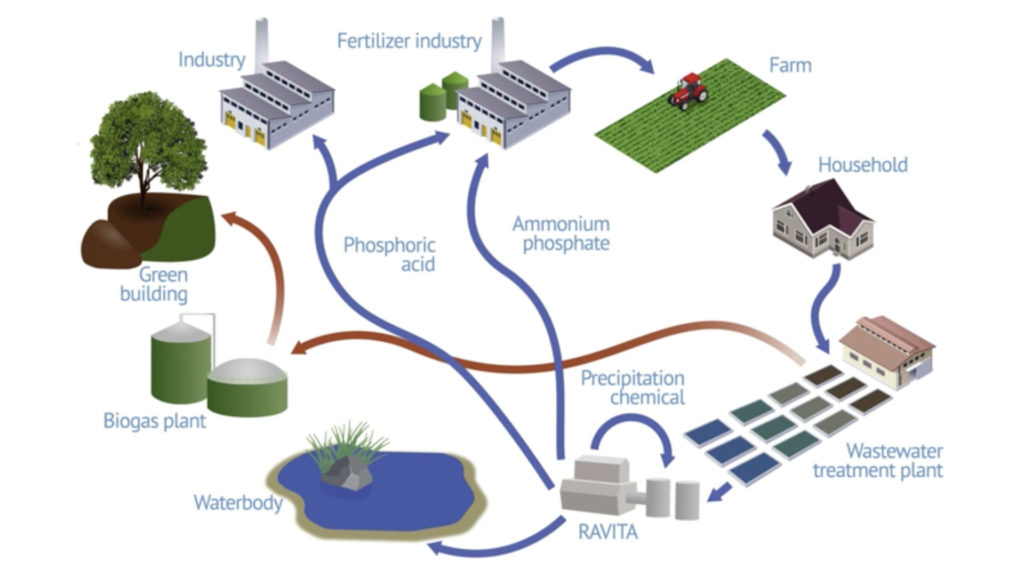

BONUS RETURN provided HSY with support by conducting a qualitative market survey (n=9 WWTPs, approx. 3 000 000 pe connected in total) directed towards wastewater treatment utilities. The RAVITA-process is intended for use in the wastewater sector with the purpose of recovering phosphorus from phosphorus-rich chemical sludge that is produced in the post-precipitation steps at wastewater treatment plants. The RAVITA process recovers phosphorus in the form of phosphoric acid at rates of 55-63% of the influent phosphorus levels (Rossi et al., 2018).

The market survey resulted in the acquisition of information useful for further development of the process. Results indicate there is a market interest in the process, benefits and increased flexibility linked to sewage sludge disposal options. However, survey participants also expressed that as a prerequisite, regulations regarding mandatory phosphorus recovery or a ban on the spreading of untreated sewage sludge on land would need to be implemented for the ecotechnology to be attractive for their operation. Furthermore, the survey revealed that the market expressed a need for certain features (e.g. automation, robustness, and a good working environment) and operational data, in order to increase the attractiveness of the process. Carrying out the market survey had the supplementary effect of promoting the existence, performance, and applicability of the RAVITA process within the wastewater treatment sector.

HSY’s RAVITA process. Image: SEI

TerraNova, Germany

TerraNova requested support from BONUS RETURN in performing an independent comparative analysis. The conducted analysis involved two technologies, the TerraNova® Ultra process, which was compared against sewage sludge mono-incineration with chemical phosphorus extraction from sludge ash. The TerraNova® Ultra ecotechnology is intended for use in the wastewater treatment sector with the functionality of recovering phosphorus and carbon originating from sewage sludge. The technology is at TRL 8, although further development and optimization is still ongoing in the nutrient recovery parts of the process.

TerraNova® Ultra processes sewage sludge into a renewable fuel, sewage sludge hydrochar, and recovers phosphorus from the sludge with a recovery rate of 60-80% in the form of solid fertilizer. The analysis revealed strengths and weaknesses for both technologies. For instance, the TerraNova® Ultra process yielded far fewer waste streams in comparison with sewage sludge mono-incineration, while sewage sludge mono-incineration had a better energy balance compared to the TerraNova® Ultra process. A comparison of phosphorus recovery rates showed that mono-incineration could achieve a higher recovery rate (95% for mono-incineration and 80% TerraNova® Ultra) but at slightly higher costs.

The TerraNova® Ultra technology. Image: Marc Buttmann, TerraNova Energy

Watch recordings of the innovators at the BONUS RETURN final conference

Kati Blomberg, RAVITA, Finland

The RAVITA process recovers phosphorus and nitrogen directly from wastewater and reject water. The phosphoric acid and ammonium phosphate products can be fed into the fertilizer cycle or other industrial uses.

Prashanth Kumar, Aquacare, Netherlands

Aquacare’s BioPhree technology is designed to reduce phosphorus to very low concentrations, which is necessary to prevent harmful algal bloom. The phosphorus is recovered in a form that can be used as a fertilizer.

Marc Buttmann, TerraNova, Germany

The TerraNova® Ultra technology converts waste sludge into two products: bio-coal and phosphorus. The technology also increases the biogas production in a wastewater treatment plant and reduces the amount of disposable waste.