Municipal officials and local business leaders in the Polish city of Słupsk aren’t waiting for the benefits of the circular economy in renewable energy production and waste recycling to come to their corner of the Baltic Sea Region. They’re making it happen now from the ground up and demonstrating how these transitions can be designed and operationalized at the city-county level. In 2020, the Słupsk Bioenergy Cluster will reach a critical milestone when completion of a new energy distribution system will link 20 participating businesses and city facilities, 40 000 electricity users and 120 000 wastewater customers – all part of an innovative renewable energy sharing and waste recycling system.

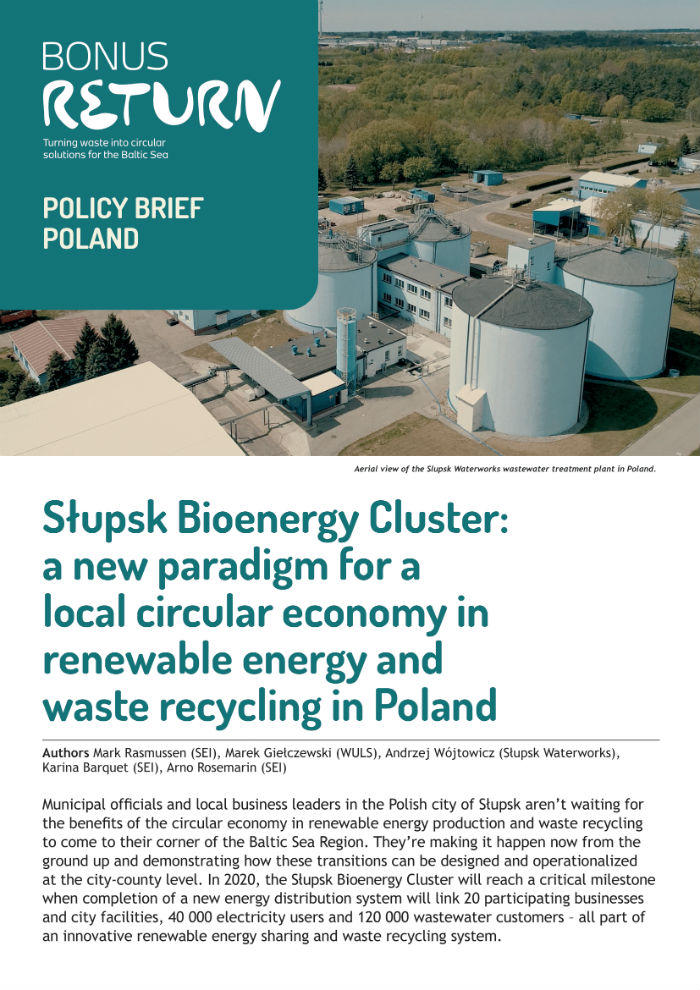

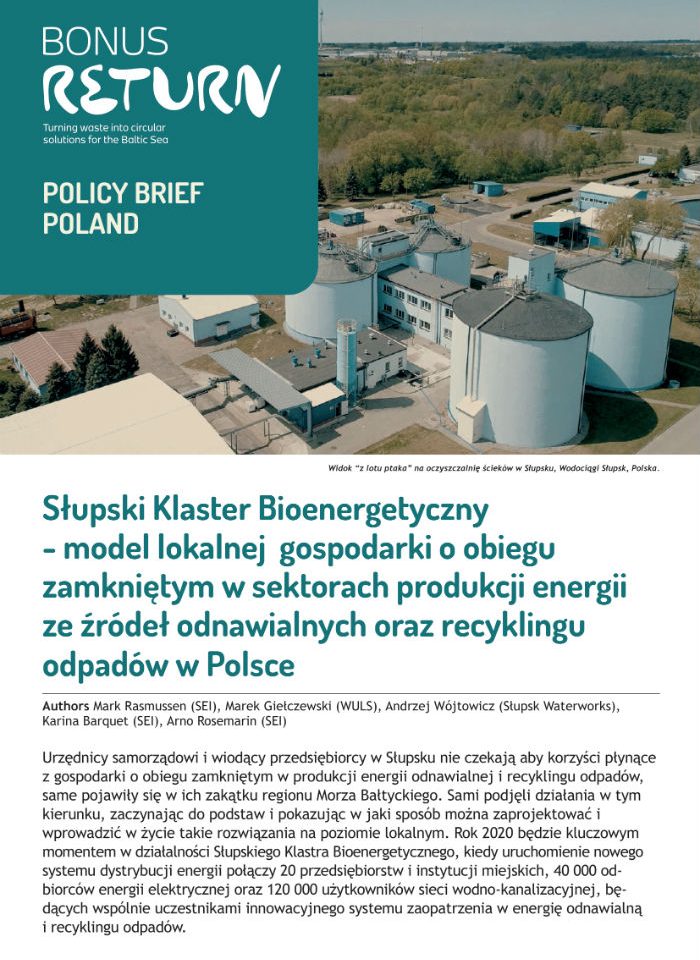

The Cluster is the brainchild of Słupsk Waterworks (Wodociągi Słupsk), the publicly owned agency that operates the Słupsk Wastewater Treatment Plant. It builds on the plant’s 20-year track record of success in pollution reduction, sludge composting and reuse, and biogas energy production. This brief looks at how this innovative cluster is serving as a living laboratory for small cities seeking to make the transition to a circular economy model, founded in low cost, shared renewable energy production and waste recycling.

Aerial view of the Slupsk Waterworks wastewater treatment plant in Poland. Image: SEI

Building on a solid foundation – Słupsk Waterworks is one of Poland’s top performers

Słupsk is located in northern Poland, near where the Słupia River drains into the Baltic Sea. Its population is approximately 90 000 and the city is the administrative centre for the surrounding county, which has approximately the same number of residents.

The Słupsk wastewater treatment plant (WWTP) is considered by many to be the model WWTP in Poland. In addition to its core function of providing the highest standard of sewage treatment, it has been a leader in biogas generation as well as sludge composting and reuse for more than 20 years. A profitable by-product is the successful BIOTOP fertilizer, which is high in phosphorus, and certified for field application, thereby returning nutrients from wastewater to the same catchment, providing an early example of a circular economy for waste.

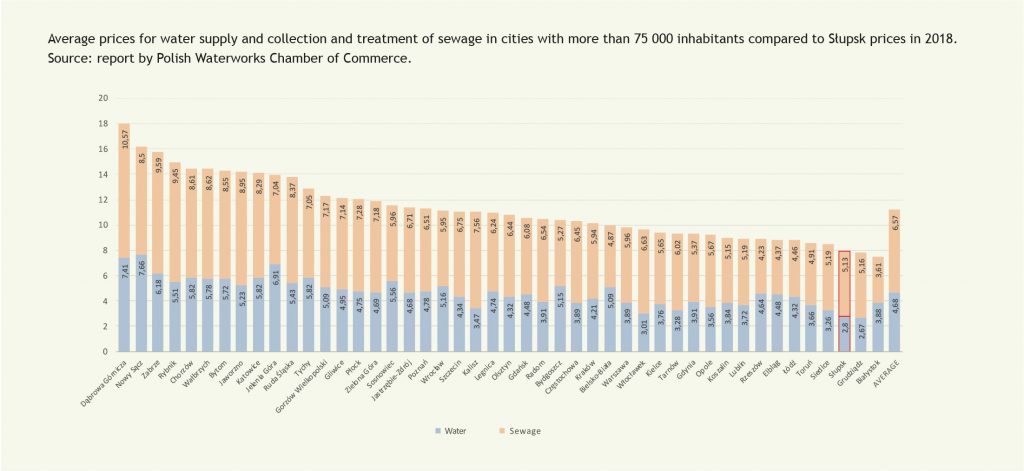

The diversification of the plant’s functions is part of the reason why Słupsk WWTP ranks as the third cheapest to run out of Poland’s 47 largest WWTPs (see graph below). This feature is an important factor in attracting and retaining businesses in the region.

Słupsk Waterworks strives to be more than a wastewater plant and thinks of itself as a regional hub for innovation in services and waste recycling that promotes economic development and environmental quality. It pursues an ambitious development vision which aims to achieve Zero Sewage (through pollutant removal, water recovery), Zero Emissions (through GHG reduction), Zero Waste (through resource recovery, organic recycling), and Zero Wasted Energy (through energy efficiency, renewable energy cluster).

This kind of leadership and proactive planning has led Słupsk Waterworks to take on its largest project to date – the development of the Słupsk Bioenergy Cluster.

The Słupsk Bioenergy Cluster

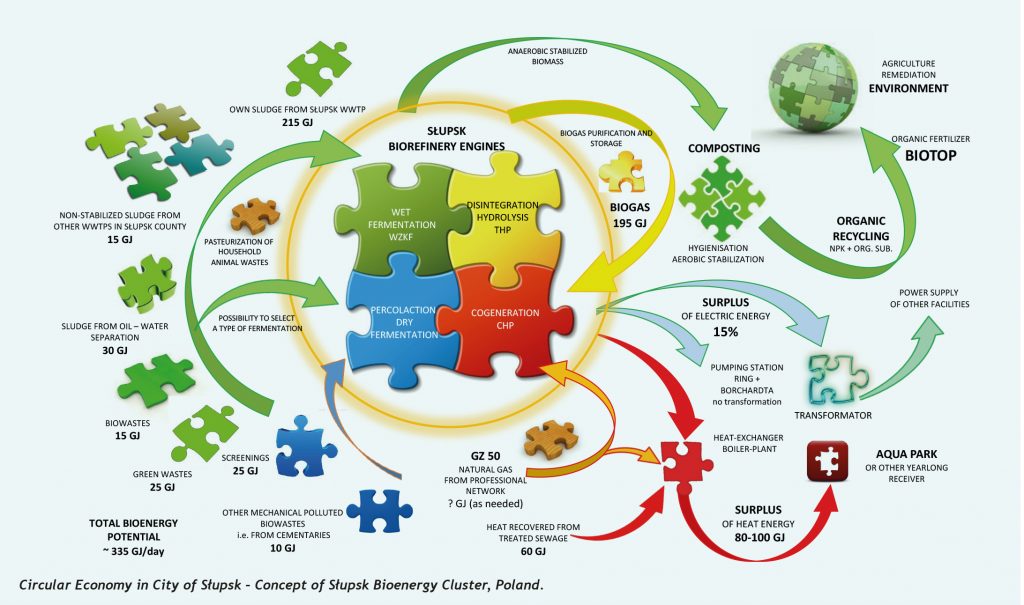

In 2015, the City of Słupsk was having a hard time providing reliable power to major energy users. They also wanted to expand the development of renewable energy in the form of wind and solar photovoltaics – new sources of power that can be difficult to integrate into old transmission systems. Słupsk Waterworks stepped in to meet this challenge as its managers saw an opportunity to leverage the tremendous community asset they had created. The Słupsk WWTP was already making electricity and heat through the generation of biogas from its sludge residues, and saw the potential in generating much more. So, they called on businesses in the area, many of which were already producing their own solar and wind energy, to join them in meeting the regional need.

“At its core, the idea was simple: you give us your waste and we all make more power together”

At its core, the idea was simple: you give us your waste and we all make more power together. The Cluster would combine energy users with energy suppliers and have all of them send their wastewater (and even their biomass waste, such as lawn clippings) to the Słupsk WWTP. By joining forces, they set out to produce more reliable, renewable electricity and heat at low costs as well as recycle more local nutrients recaptured from the sewage sludge.

The Słupsk Bioenergy Cluster was officially formed in October 2017 with 19 founding members, both generators and users of energy, all of which were waste producers. Słupsk Waterworks was established as the managing coordinator of the initiative as well as a contributing energy partner.

The scope of the Cluster is defined by its generation of electricity, heat and biofuels in both conventional and renewable energy installations. But its holistic approach also sees them working on the distribution, balancing and storage of energy for members, waste recycling and local reuse, energy efficiency and renewable vehicle and transport system improvements across the Cluster, and research, marketing and education programmes related to spreading their model to other regions.

While much has been accomplished, the fruits of the Cluster won’t be fully realized until 2020, when its distribution system linking all partners is completed. An early challenge identified by the partners was the need to build their own electricity grid capable of handling renewables and to “work around” the area’s major established energy suppliers (primarily coal-based) who won’t allow them to use their transmission lines. But because the aim of the cluster is not to put energy into the main system, but to supply the cluster members with renewable energy from a reliable source, the system was designed to be self-sufficient in terms of energy production and use.

What are the potential gains for the circular economy?

Słupsk Waterworks reports that there is currently a queue for joining the Cluster and there are already plans for opening the partnership to new entrants once the distribution network is built. The driver for businesses and customers is access to stable, renewable, cheaper energy. Słupsk WWTP plays the unique role of merging sludge-generated biogas (for returning into the Cluster system as heat) and sludge composting (with its resulting recycled phosphorus fertilizer product) into the primary energy scheme. It is a strong example of how whole-system thinking can lead to new opportunities to craft circular economy solutions.

The Słupsk Bioenergy Cluster provides a framework for overcoming many of the multidimensional barriers affecting new circular economy innovations. First, it is grounded in the capabilities of Słupsk Waterworks and its 20 years of technical experience at the WWTP. Second, it has worked hard to earn support and financing from local and national government as well as from the EU, thereby easing the transitions in policy and infrastructure investments needed for the cluster concept to succeed. Lastly, the effort is highly coordinated between municipal officials and business partners in an open collaboration based on well-articulated goals and responsibilities. It is for these reasons that the Polish Ministry of Energy has twice recognized the Cluster as a national model.

BIOTOP Fertilizer

Since 2004, the Słupsk wastewater treatment plant has produced a crop fertilizer from composted sludge at the facility (90% of the sludge is composted). The product is highly desired for its high nutrient content, particularly of phosphorus at 3% (as P2O5). BIOTOP is used primarily by large agricultural businesses in Słupsk County, thereby returning a portion of wastewater generated in the area back into local food production in a closed loop.

The Polish Centre for Testing and Certification regularly tests BIOTOP for compliance with chemical standards in a similar way to the REVAQ system used in Sweden. This helps ensure low concentrations of heavy metals in the resulting fertilizer. Nevertheless, there is still some concern about contaminants. Many countries are looking to ban all wastewater sludge reuse on farmlands due to concerns about emerging contaminants such as pharmaceuticals and microplastics, which may mean Słupsk Waterworks will need to continue to innovate and adapt to meet new goals for reducing pollution.

The design of the Słupsk Bioenergy Cluster and its transition from idea to functional infrastructure exposes policy and regulatory changes needed to advance similar decentralized, energy-waste reuse systems in the Baltic Sea Region.

- The locked-in position of large, traditional fossil-fuel based energy companies presents serious challenges to the integration of distributed, renewable energy sources. The Słupsk Bioenergy Cluster has been required to construct a parallel energy distribution network for its partners. National policy changes are required to provide new local producers of renewable energy better access to the existing energy market.

- All levels of government can do more to stimulate cooperation platforms such as the Słupsk Bioenergy Cluster, especially through incentives for developing local energy production from renewable sources. For example, encouraging the integration of waste recycling in the energy production system through enhanced tax system incentives would help guide the energy sector toward more circular economy solutions.

- Beyond the local level, faster and effective implementation of European Union regulations (e.g. the “RED II” directive (2018/2001) “on the promotion of the use of energy from renewable sources”) and initiatives (e.g. Clean Energy for all Europeans Package – the so-called “Winter Package”) into national legal and implementation systems would ease the scaling-up of models such as Słupsk Bioenergy Cluster. There is presently a gap between supportive, aspirational goals in EU policy and local innovation.

Aerial view of a field in Slupsk, Poland.

This series of three briefs describes real-world examples of policies or programmes intended to accelerate implementation of ecotechnologies that reduce nutrient losses, and encourage nutrient reuse in the three BONUS RETURN case study basins: Fyrisån (Sweden), Vantaanjoki (Finland) and Słupia (Poland).